Research Theme

APUs for Heavy-duty Trucks

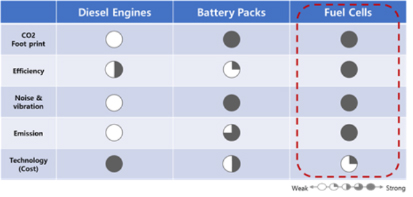

Heavy-duty trucks are widely used around the world for delivering large volumes of goods between distant areas. To meet the truck drivers’ needs, there are many conveniences such as air conditioners, refrigerators, and cooking appliances inside the cabs of heavy-duty trucks. In order to use those electrical appliances, truck drivers usually idle the engine to produce electricity. However, engine idling has several disadvantages including noise and air pollution. Diesel engines produce noise and vibration during their operation, even when they are operating at a low RPM. With the noise and vibration, the nighttime use of diesel engines is restricted. Engine idling also produces enormous amounts of pollutants such as NOx and PMs. Additionally, fuel efficiency is very low during idling compared to normal driving conditions. Therefore, some states in the U.S. have started to prohibit engine idling by law. It is clear that another way to produce electrical energy is required for heavy-duty trucks.

The Development of a Diesel-based SOFC Unit

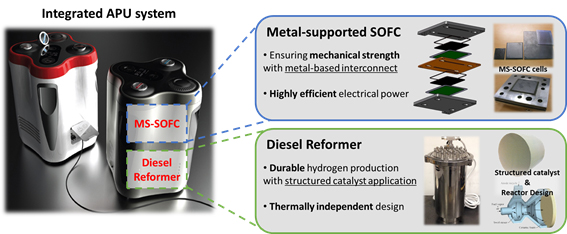

There is an ‘eco-friendly’ way to achieve this goal. A diesel-powered Auxiliary Power Unit (APU) system is being proposed as a solution that utilizes more robust metal-supported Solid Oxide Fuel Cell (SOFC) technology. Metal-supported SOFCs have been investigated by Professor Joongmyeon Bae’s group at KAIST and its associate company, H&Power, in an effort to overcome the intrinsic problems of ceramic-based SOFCs, such as poor sealing, mechanical issues, and thermal shock vulnerabilities. The metal-supported SOFC cells developed by H&Power showed excellent mechanical strength, good thermal shock resistance, and easy sealing compared with conventional ceramic-based cells. The resulting design is currently at the cell-stack level and is considered to be a realistic possibility for APU applications for heavy duty trucks

Although there are promising expectations for an SOFC-based APU system, the major problem with the current system is unstable system performance. To accomplish long-term performance, a catalyst deactivation problem due to carbon deposition on the catalyst surface must be solved. Sulfur and aromatic compounds in the fuel have been identified as the main factors influencing carbon deposition in the diesel reformer. The number of active sites on the catalyst is diminished by sulfur poisoning and by the formation of carbon. Additionally, aromatic compounds are usually converted to olefins such as ethylene, which is a typical precursor of carbon formation. The SOFC also incurs a carbon deposition problem at the anode when using hydrocarbons as a fuel. Mechanical strength, thermal shock resistance, and sealing are the other major issues that must be dealt with before SOFCs are feasible for wider commercial use.

APU Project at the Saudi Aramco-KAIST CO2 Management Center

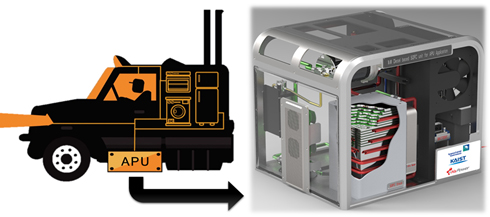

Saudi Aramco, a Saudi Arabian national petroleum and natural gas company, has created the Saudi-Aramco-KAIST CO2 Management Center at the KAIST campus in Daejeon. The center’s main goal is finding solutions to carbon management and one of the funded projects deals with SOFC-based APUs for heavy-duty trucks. From previous research projects between Saudi Aramco and KAIST, fuel injectors and post processors were introduced to maintain stable reforming. The integrated diesel reformer was successfully operated for 2500 hours (for the first time in the world). Also, a structured catalyst was developed for a 1kW pre-reforming reactor. Using design factors from previous research projects, a 1kW diesel reformer was fabricated for the APU project. The project will deliver a first-of-its-kind APU system with a metal-supported SOFC that will be utilized. In terms of the overall efficiency and durability, the prototype will demonstrate the clear benefits of a diesel reformer and metal-supported SOFC system over the ceramic SOFC APU using commercial diesel.

- Production of hydrogen from commercial fuels with high efficiency

- Fabrication of fuel cell devices that have high energy efficiency

- Reforming technology, which is hydrogen extraction from commercial hydrocarbon with high efficiency

- Solid oxide fuel cell technology, which is a highly efficient energy conversion device operating at high temperature

- Heat management and engineering technology, which enhances the total thermal efficiency of target devices