Prof. Dai-gil, Lee Director of KI for Design Complex Systems (KIDCS) has successfully developed industry’s first membrane-type cargo hold for LNG tankers with Samsung Heavy Industries.

With this, the company has finally tackled the last unsolved development initiative for the Korean shipbuilding industry, which was the cargo hold manufacturing technology for LNG tankers, completing a self-reliant Korean shipbuilding ecosystem.

As this technology will enable cost savings of KRW 9 billion to KRW 10 billion per LNG tanker, it is expected that SHI will be able to increase its LNG shipbuilding competitiveness.

The cargo hold for LNG tankers is a tank containing LNG that is liquefied at -163 degrees, and is a critical part of an LNG tanker.

In the past, all Korean shipbuilders manufacturing LNG tankers had to pay technology royalties, as a foreign company had the source technology.

With the aim of achieving self-reliant cargo hold manufacturing, Samsung Heavy Industries has conducted joint research with KAIST since 2007, with the master design and full design certified by major classification agencies, including LR and ABS.

In April 2011, the Company completed the mock-up certification and has undertaken phased preparation for the product launch by having tech briefings for the world’s major oil companies, including BG, Chevron, CoP and Exxon Mobil.

The newly developed cargo hold for LNG tankers was built with tech upgrades, including improved membrane forms, newly developed secondary barrier materials and super-insulating materials, in order to improve stability, gas tightness and efficiency in transportation.

Won the Largh-scale Convergence Project Contract [2012-01-12]

Won the Largh-scale Convergence Project Contract [2012-01-12]

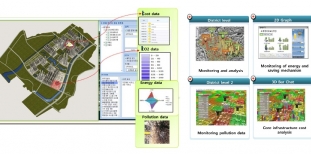

KIUSS Research Contract on the Branch of 'Smart Green City' [...

KIUSS Research Contract on the Branch of 'Smart Green City' [...