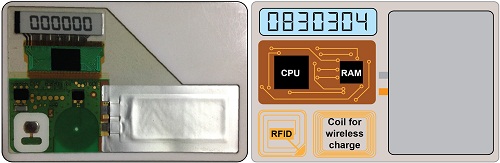

Since the battery can be charged wirelessly, useful applications are expected including medical patches and smart cards.

Professor Jang Wook Choi at KAIST’s Graduate School of Energy, Environment, Water, and Sustainability (EEWS) and Dr. Jae Yong Song at the Korea Research Institute of Standards and Science jointly led research to invent a flexible lithium ion battery that is thinner than a credit card and can be charged wirelessly.

Their research findings were published online in Nano Letters on March 6, 2015. Lithium ion batteries are widely used today in various electronics including mobile devices and electronic cars. Researchers said that their work could help accelerate the development of flexible and wearable electronics.

Conventional lithium ion batteries are manufactured based on a layering technology, stacking up anodes, separating films, and cathodes like a sandwich, which makes it difficult to reduce their thickness. In addition, friction arises between layers, making the batteries impossible to bend. The coating films of electrodes easily come off, which contributes to the batteries’ poor performance.

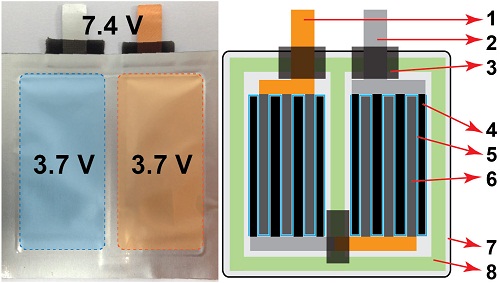

The research team abandoned the existing production technology. Instead, they removed the separating films, layered the cathodes and anodes collinearly on a plane, and created a partition between electrodes to eliminate potential problems, such as short circuits and voltage dips, commonly present in lithium ion batteries.

After more than five thousand consecutive flexing experiments, the research team confirmed the possibility of a more flexible electrode structure while maintaining the battery performance comparable to the level of current lithium ion batteries.

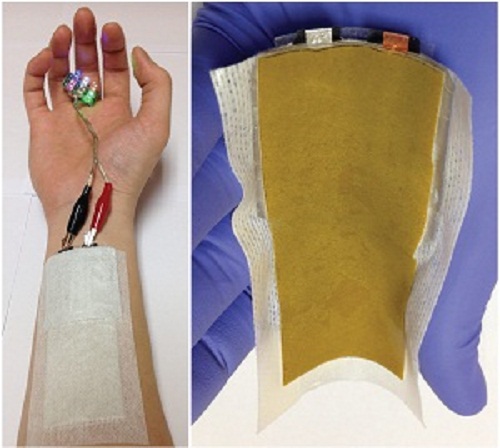

Flexible batteries can be applied to integrated smart cards, cosmetic and medical patches, and skin adhesive sensors that can control a computer with voice commands or gesture as seen in the movie “Iron Man.”

Moreover, the team has successfully developed wireless-charging technology using electromagnetic induction and solar batteries.

They are currently developing a mass production process to combine this planar battery technology and printing, to ultimately create a new paradigm to print semiconductors and batteries using 3D printers.

Professor Choi said, “This new technology will contribute to diversifying patch functions as it is applicable to power various adhesive medical patches.”

Picture 1: Medical patch (left) and flexible secondary battery (right)

Picture 2: Diagram of flexible battery

Picture 3: Smart card embedding flexible battery

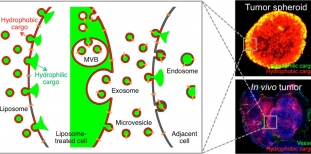

Anti-Cancer Therapy Delivering Drug to an Tumor Developed by ...

Anti-Cancer Therapy Delivering Drug to an Tumor Developed by ...

조병진, 임성갑, 유승협 교수 휘어지는 10나노미터 고분자 절연막...

조병진, 임성갑, 유승협 교수 휘어지는 10나노미터 고분자 절연막...